At Ulkasemi we specialize in providing high-quality technical support to leading semiconductor foundries. Our expertise in process engineering, quality assurance, and design verification ensures that our clients achieve maximum efficiency and yield in their manufacturing operations.

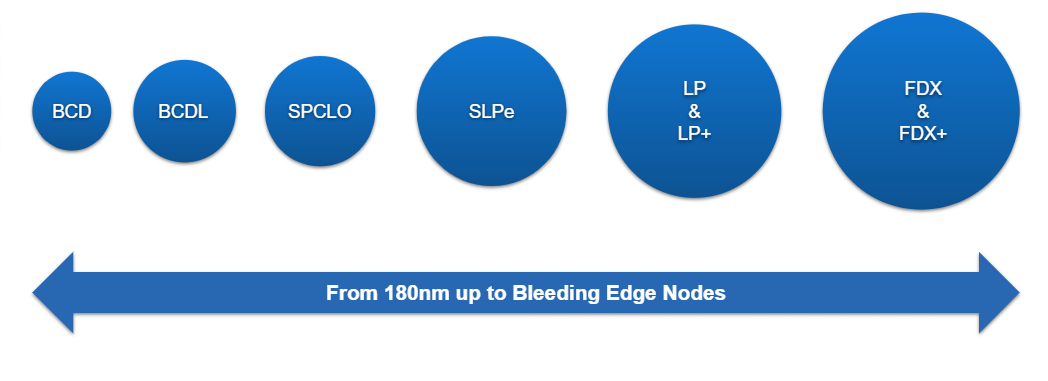

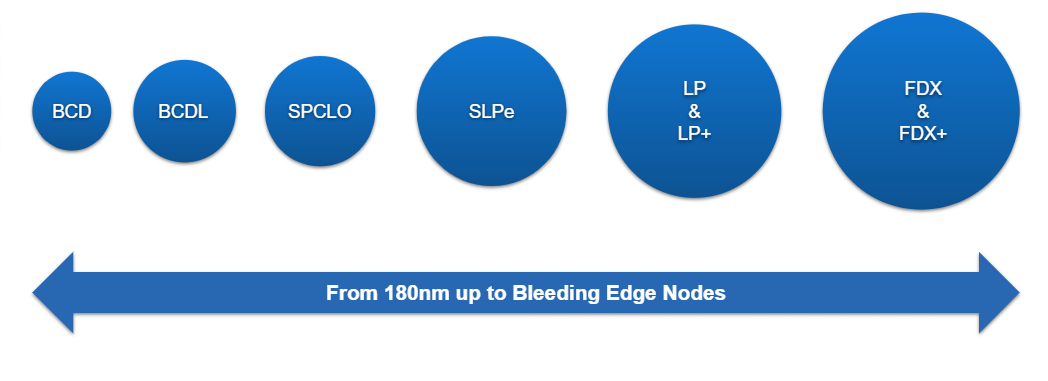

Expertise in Technology Nodes

With deep expertise in semiconductor design and development, we offer premier Foundry Design Services across a wide range of technology nodes, including Planar CMOS, FinFET, FD-SOI, and Silicon Photonics. These advanced technologies power a wide range of applications, from AI and IoT to consumer electronics, power management devices, telecommunications, and automotive systems. By harnessing our technical excellence, we deliver high-performance, efficient, and scalable semiconductor solutions that drive innovation across diverse industries.

Our Standard Cell Library Development Support service assists semiconductor companies in designing, optimizing, and validating high-performance standard cell libraries tailored to specific process nodes and design requirements. We have experience of developing standard cell libraries in different technology nodes starting from 180nm to bleeding edge.

We have experience of working on Custom memory, Designing, optimizing, and generating memory IPs (SRAM, DRAM, RRAM, etc.) for specific performance, power, and area requirements. Also experience in memory compiler development, adapting existing memory designs for new technology nodes while ensuring compliance with foundry design rules.

We provide automation and scripting support for foundries by developing custom tools and workflows to improve efficiency in design, verification, and analysis. Our solutions help automate processes, enhance analytical accuracy, and ensure high-quality analysis. By optimizing repetitive tasks, we improve precision and speed up the tap-out process for semiconductor development.

We focus on quality assurance and testing of intellectual property (IP) blocks to ensure functionality, performance, and reliability across different technology nodes. This includes validating IP deliverables, debugging issues, and ensuring seamless integration into larger designs. We also verify compliance with process-specific requirements for nodes ranging from mature technologies to advanced nodes.

We provide support for Library Characterization & Validation to ensure that standard cell libraries and memory IPs meet foundry and design requirements. Our services include timing, power, and noise analysis across different process, voltage, and temperature (PVT) conditions to optimize power, performance, and area (PPA).

We provide comprehensive Process Migration support to help ensure a seamless transition across different semiconductor process nodes. Our services include adapting designs to new process technologies, optimizing performance, power, and area (PPA), and ensuring compatibility with existing manufacturing standards. We assist in validating process technology changes, performing design rule checks (DRC), layout versus schematic (LVS) checks, and ensuring compliance with electrical and thermal requirements.

We provide comprehensive support in Circuit Simulation, Analysis, and Model Hardware Correlation (MHC) to ensure that designs are both optimized and manufacturable. Our services include performing detailed circuit simulations to analyze key electrical parameters such as timing, power, noise, and signal integrity under varying conditions, helping to predict circuit behavior before fabrication. We also conduct in-depth circuit analysis to identify potential issues, optimize power consumption, reduce noise, and address performance bottlenecks. Additionally, through Model Hardware Correlation, we compare simulation results with actual hardware measurements, ensuring that design models accurately reflect real-world performance, and fine-tune the models for improved accuracy and reliability.

We provide dedicated MPW (Multi-Project Wafer) support to assist in the efficient development and testing of integrated circuits (ICs) across multiple projects within a single wafer run. Our services include coordinating the design, validation, and tape-out processes to ensure that designs meet both performance and manufacturability requirements